Revolutionizing 3D Nanolithography with Metalens Arrays and Adaptive Illumination

Innovations in 3D Nanolithography with Metalens Arrays and Adaptive Illumination

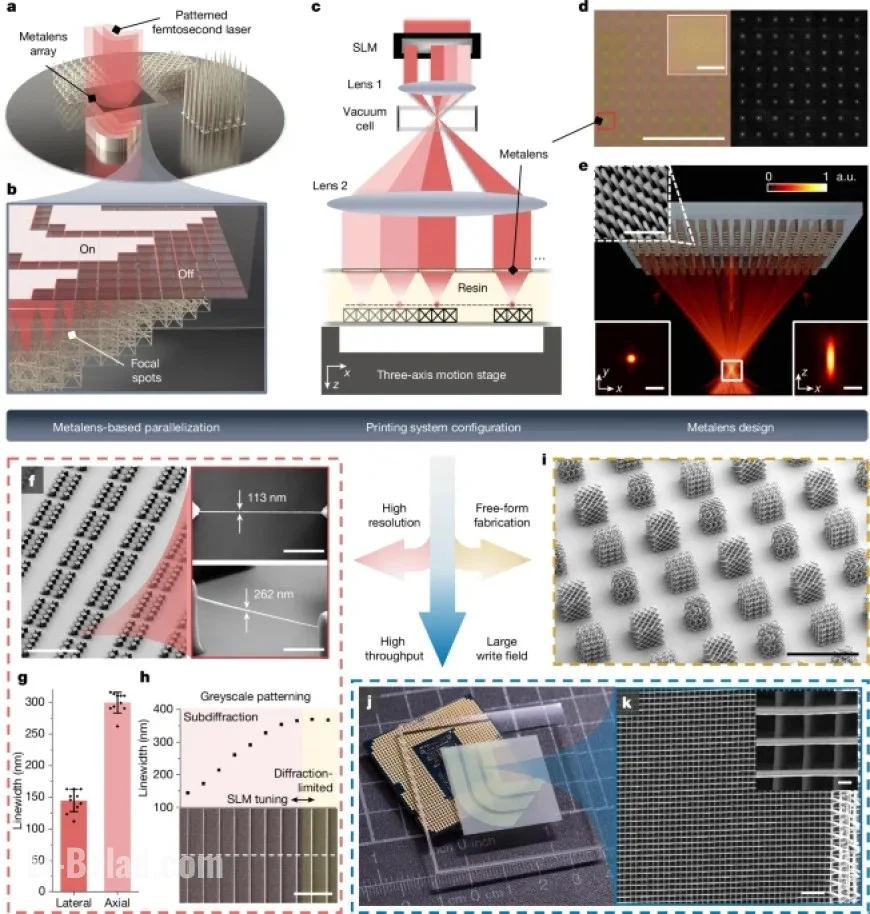

Recent advancements in 3D nanolithography are revolutionizing the field of microfabrication. The integration of metalens arrays and adaptive illumination techniques is now at the forefront of these innovations. This article explores the key trends and developments shaping this technology.

Metalens Arrays: A Game Changer in Photonics

Metalenses are flat optical devices made from subwavelength structures. Unlike traditional lenses, they manipulate light through nanostructured materials. These arrays are particularly advantageous in applications requiring compact size and light management.

Recent studies have demonstrated the performance of metalens systems in enhancing imaging and focusing capabilities. For instance, they enable high-resolution manufacturing processes that are essential for creating intricate microdevices.

Adaptive Illumination Techniques

Adaptive illumination complements metalens technology by dynamically controlling light distribution. This advancement leads to improved precision during the 3D printing process. By adapting to the material and the geometry of the object, these techniques optimize performance and reduce fabrication errors.

Key Applications and Benefits

The implications of these technologies span various fields. From biomedical devices to photonic applications, the efficiency of micro-scale manufacturing is greatly enhanced.

- Biomedical Engineering: Metalens arrays facilitate the development of advanced imaging systems and medical devices.

- Quantum Computing: Enhanced light manipulation might lead to significant advancements in quantum information technologies.

- Optoelectronics: These innovations contribute to the miniaturization of devices, making them more efficient.

Recent Research Findings

1. Direct Light Manipulation: Recent experiments show that combining metalens with adaptive systems allows for precise control of light pathways.

2. High-Resolution Objectives: Studies indicate that these technologies can achieve resolutions below 200 nm, which is critical for next-generation devices.

3. Improved Fabrication Rates: With the new methodologies, production times for microfabrication are significantly reduced.

The Future of 3D Nanolithography

As research progresses, the potential for combining metalens arrays and adaptive illumination in 3D nanolithography expands. Future innovations could further enhance functionality, making it a cornerstone of modern manufacturing in numerous sectors.

In conclusion, the intersection of metalens technology and adaptive illumination is set to redefine the landscape of 3D nanolithography. Aiming for better precision and efficiency will lead to new horizons in microfabrication technology.