Laser Engraving in Glass Enhances Fast, Dense Archival Data Storage

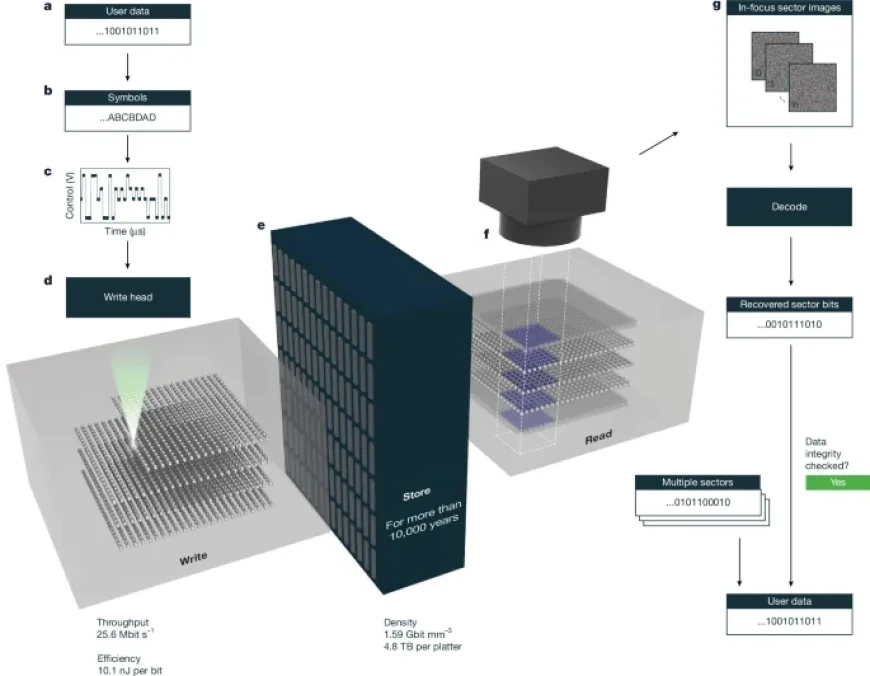

Laser engraving in glass is emerging as a transformative approach to dense archival data storage. This innovative technique allows for the precise writing of voxels, enabling high-quality data retention in various glass materials. This article discusses the key components, metrics, and methodologies behind the laser engraving process, showcasing how it enhances data storage capabilities.

Key Metrics for Laser Engraving in Glass

The evaluation of the silica storage system involves several critical metrics:

- Voxel Quality (Q): Determined by the formula Q = B/nV, where B represents the number of user bits stored, and nV is the number of voxels. This metric also considers redundant bits for error correction, leading to quality factor q = Q/Qw.

- Data Density (ρ): Calculated as ρ = Q/V (Gbit mm−3), where V is derived from the dimensions of the glass.

- Usable Capacity: The total user bits that can be stored, adjusted for overhead, measured in terabytes (TB) per glass platter.

- Write Throughput (θ): Measured in bit/s, related to the laser repetition rate and number of beam lines.

- Write Efficiency (η): The energy consumed to write each user bit, aiming for lower values to optimize performance.

- Lifetime: Experimental estimates related to how long the data remains intact within the glass.

Components of the Writing System

Central to the laser engraving process is the femtosecond laser system. The setup includes:

- Laser Source: An amplified femtosecond laser, with operational wavelengths and tunable pulse durations.

- Optical Configuration: Comprising of beam splitters and modulators tailored for specific voxel types (birefringent or phase voxels).

- Scanning Mechanism: A polygon scanner enables precise laser pulse direction over the glass surface.

Writing Mechanisms

Two primary writing mechanisms are used for creating different voxel types:

- Birefringent Voxels: Achieved using pseudo-single-pulse regime techniques, specifically designed to manage polarization and modulation of laser pulses.

- Phase Voxels: Achieved through amplitude modulation, allowing for the precise control of the data stored within the glass medium.

Emissions-Based Control Techniques

The writing process incorporates advanced emissions-based control for optimizing voxel accuracy.

- Feedback Systems: Utilize photoemission from voxel writing to maintain precision during the engraving process.

- Calibration Mechanisms: Ensure consistent results across different scanning conditions and improve overall write efficiency.

Readout Methods and Machine Learning Integration

Data retrieval from the engraved glass employs sophisticated optical systems and machine learning models:

- Wide-field Microscope Setup: Used for reading both birefringent and phase voxels with appropriate illumination and detection methodologies.

- Machine Learning Decoding: Employs convolutional neural networks (CNNs) to infer symbols from read images, enhancing data recovery and reducing error rates.

Conclusion

Laser engraving in glass represents a significant advancement in data storage technology. By leveraging multiple metrics and sophisticated techniques, this method achieves high data density and longevity. As research continues, its potential for revolutionizing archival data storage is evident.